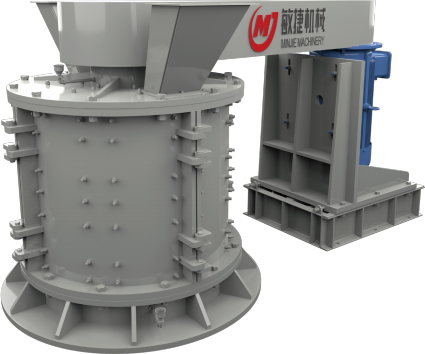

The Ordinary Ball Mill, designed by Fujian Minjie Machinery Co., Ltd., is an essential piece of equipment for the ceramic industry, specifically for the mixing and fine grinding of ceramic raw materials. This intermittent ball mill covers a wide range of specifications, from small capacity test mills with a 0.05-ton capacity to large production mills with a 60-ton capacity. It offers two types of transmission methods: belt transmission and hard tooth reducer transmission. For ball mills with a capacity of 8 tons or less, the structure is an integral frame, while larger models are installed on a cement foundation with a separate cylinder and frame. The ball mill is known for its high efficiency, low energy consumption, large output, good quality, and smooth operation. It is easy to operate and maintain, making it a reliable choice for ceramic material processing.

Product Highlights:

- Advanced Cylinder Rolling: The cylinder is crafted using a new CNC rolling machine, ensuring excellent ovality and no straight edges.

- Precise Vertical Splicing: The vertical splicing technique guarantees the cylinder's good coaxiality and straightness.

- High-Precision Processing: The belt position and both ends' bearing positions are processed using a large floor-mounted lathe, ensuring stability, low current fluctuations, and energy efficiency.

- Stress-Relieved End Heads: The end heads undergo annealing treatment in a large furnace to eliminate welding stress, extending the equipment's service life.

- Enhanced Shaft Head Durability: The shaft head is subjected to non-destructive testing and normalizing treatment after rough machining, ensuring better strength and longevity.

- Efficient Transmission: The option to use a hard tooth reducer enhances transmission efficiency, reduces noise, and saves energy. Additionally, the patented gearbox bearing clearance adjustment technology (Patent No: 201020685450.6) extends the service life.

Product Details:

Product Specifications:

Serial Number | Model | Tonnage | Capacity (L) | Cylinder Size (mm) | Main Motor Power (kW) | Maximum Usage Conditions | Start Mode | Lining | Grinding Media | Notes |

1 | Q0607 | 0.05 | 200 | Ø600x700 (Minouchi) | 1.5-6 | High Alumina | Direct | High Alumina | High Alumina |

|

2 | Q0709 | 0.1 | 330 | Ø700x900 (Minouchi) | 2.2-6 | High Alumina | Direct | High Alumina | High Alumina |

|

3 | Q0911 | 0.2 | 680 | Ø900x1100 (Minouchi) | 45357 | High Alumina | Direct | High Alumina | High Alumina |

|

4 | Q1113 | 0.3 | 1200 | Ø1100x1300 (Minouchi) | 45388 | High Alumina | Direct | High Alumina | High Alumina |

|

5 | Q1315 | 0.5 | 2000 | Ø1300x1500 (Minouchi) | 5.5-6 | High Alumina | Direct | High Alumina | High Alumina |

|

6 | Q1618 | 1 | 3500 | Ø1600x1800 (Minouchi) | 45602 | High Alumina | Direct | High Alumina | High Alumina |

|

7 | Q1820 | 1.5 | 5000 | Ø1800x2000 (Minouchi) | 45458 | High Alumina | Direct | High Alumina | High Alumina |

|

8 | Q1920 | 2 | 5320 | Ø1900x2000 (Minouchi) | 18.5-6 | High Alumina | Direct | High Alumina | High Alumina |

|

9 | Q2124D | 3 | 7700 | Ø2100x2400 (Minouchi) | 45473 | High Alumina | Frequency Conversion | High Alumina | High Alumina |

|

10 | Q2426A | 5 | 10700 | Ø2400x2600 (Minouchi) | 13667 | High Alumina | Frequency Conversion | High Alumina | High Alumina |

|

11 | Q2426C | 5 | 10700 | Ø2400x2600 (Minouchi) | 16589 | High Alumina | Frequency Conversion | High Alumina | High Alumina |

|

12 | Q2628 | 6 | 13800 | Ø2600x2800 (Minouchi) | 16589 | High Alumina | Frequency Conversion | High Alumina | High Alumina |

|

13 | Q2628A | 6 | 13800 | Ø2600x2800 (Minouchi) | 16589 | High Alumina | Frequency Conversion | High Alumina | High Alumina |

|

14 | Q2832 | 8 | 18200 | Ø2800x3200 (Minouchi) | 20241 | Chalco | Frequency Conversion | Chalco | Chalco |

|

15 | Q3038 | 10 | 24550 | Ø3000x3800 (Minouchi) | 20241 | Chalco | Frequency Conversion | Chalco | Chalco |

|

16 | QJ3246 | 15 | 34000 | Ø3200x4600 (Minouchi) | 32964 | High Alumina | Frequency Conversion | High Alumina | High Alumina |

|

17 | Q3244T | 15 | 32000 | Ø3200x4400 (Minouchi) | 280-6 | High Alumina | Frequency Conversion | High Alumina | High Alumina | Belt position double layer |

18 | Q3352 | 20 | 41200 | Ø3300x5225 (Minouchi) | 33086 | Chalco | Frequency Conversion | Chalco | Chalco |

|

19 | QJ3352 | 20 | 41200 | Ø3300x5225 (Minouchi) | 110-4 | High Alumina | Frequency Conversion | High Alumina | High Alumina |

|

20 | Q3358 | 25 | 45000 | Ø3300x5800 (Minouchi) | 33086 | Chalco | Frequency Conversion | Chalco | Chalco |

|

21 | QJ3358 | 25 | 45000 | Ø3300x5800 (Minouchi) | 132-4 | High Alumina | Frequency Conversion | High Alumina | High Alumina |

|

22 | QJ3564 | 35 | 58000 | Ø3532x6468 (Minouchi) | 160-4 | High Alumina | Frequency Conversion | High Alumina | High Alumina |

|

23 | QJ3672 | 40 | 67000 | Ø3600x7200 (Minouchi) | 200-4 | High Alumina | Frequency Conversion | High Alumina | High Alumina | Reinforced |

24 | QJ3672T | 40 | 67000 | Ø3600x7200 (Minouchi) | 160-4 | High Alumina | Frequency Conversion | High Alumina | High Alumina | Reinforced |

25 | QJ3875 | 50 | 85000 | Ø3836x8000 (Minouchi) | 200-4 | High Alumina | Frequency Conversion | High Alumina | High Alumina |

|

26 | QJ4086T | 60 | 100000 | Ø4036x8600 (Minouchi) | 250-6 | High Alumina | Frequency Conversion | High Alumina | High Alumina | ZLY450 |

27 | QJ4290 | 80 | 114100 | Ø4200x9000 (Minouchi) | 315/355-6 | High Alumina | Frequency Conversion | High Alumina | High Alumina | ZLY500/ZLY560 |

28 | QJ42110 | 100 | 141300 | Ø4200x11000 (Minouchi) | 355/400-6 | High Alumina | Frequency Conversion | High Alumina | High Alumina | ZLY560 |